Rotary Vacuum Paddle Dryer is horizontal, mechanically agitated vacuum dryer, which gives low temperature drying, mixing and breaking effects simultaneously. The apply of vacuum is to lower the boiling point of water or solvents contained in wet material to be dried.

RVPD consists of a jacketed cylindrical vessel and a hollow rotor fitted with double-walled discs to considerably increase heating surface. Heating medium, such as steam, hot water or hot thermal oil, is forced to circulate both inside the jacket and hollow rotor to form heating surface.

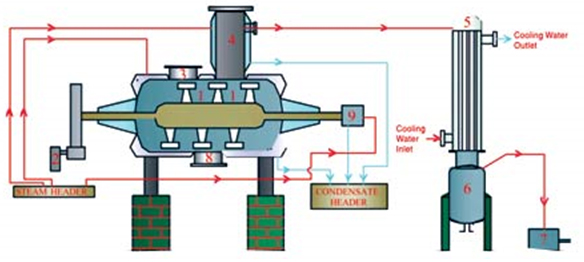

Wet material is gravity fed into the drying chamber via the infeed port with screw feeder, then vacuum and heat are applied to reach the evaporation point of water or solvents contained in wet material. Meanwhile, the disc rotor rotates in different directions to completely mix, move and break the wet material for fast and uniform heat transfer. Moisture evaporates rapidly and is extracted as vapor by the vacuum pump. Tubular condenser is installed to recover the evaporated moisture. The drying process can be batch or continuous operation.

Rotary Vacuum Paddle Dryer is ideally suited for low temperature drying of wet powders, filter cakes, sticky pastes or slurry materials in various industries with the following special features:

Salient Features :-

Bodies may be of cylindrical or rectangular cross section. Both shelves and body are heated (the body to prevent internal condensation) with controlled circulation of hot water, steam or dia thermic fluid. Vacuum is drawn through large diameter ducts to minimize pressure drops and produce minimum working pressures. Both rotary and static dryers can be supplied with the following Optional ancillaries.

schematic drawing of Rotary vacuum Padel dryer

Features :-

| MODEL NO. | TOTAL VOLUME (Lits) | WORKING VOLUME (Lits.) | OVERALL DIMENSIONS (mm) | POWER (H.P.) | |||

| A | B | C | D | ||||

| RVPD-1 | 100 | 50 | 2250 | 650 | 1400 | 400 | 3 |

| RVPD-2 | 200 | 125 | 2350 | 750 | 1500 | 400 | 5 |

| RVPD-5 | 500 | 250 | 2800 | 900 | 1600 | 400 | 7.5 |

| RVPD-10 | 1000 | 500 | 3900 | 1050 | 1750 | 300 | 10 |

| RVPD-15 | 1500 | 750 | 4500 | 1150 | 1850 | 300 | 12.5 |

| RVPD-20 | 2000 | 1000 | 5500 | 1250 | 2000 | 300 | 15 |

| RVPD-30 | 3000 | 1500 | 6250 | 1350 | 2200 | 300 | 20 |

| RVPD-40 | 4000 | 2000 | 5800 | 1450 | 2300 | 200 | 25 |

| RVPD-50 | 5000 | 2500 | 7550 | 1500 | 2400 | 200 | 30 |

| RVPD-60 | 6000 | 3000 | 8250 | 1750 | 2500 | 200 | 30 |

| RVPD-80 | 8000 | 4000 | 8450 | 1800 | 2700 | 200 | 40 |

| RVPD-100 | 10000 | 5000 | 10000 | 1850 | 2800 | 200 | 50 |

| RVPD-120 | 12000 | 6000 | 10400 | 1950 | 3100 | 200 | 60 |

| RVPD-160 | 15000 | 7500 | 11100 | 2200 | 3500 | 200 | 75 |

| RVPD-200 | 20000 | 10000 | 11550 | 2700 | 4100 | 200 | 100 |

| RVPD-250 | 25000 | 13000 | 12000 | 3000 | 5300 | 200 | 150 |

| NOTE: Design & Dimensions of above are subject to change without notice. | |||||||