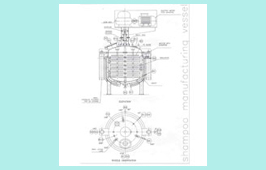

The Shampoo Mixers or Shampoo Mixing Machine assemblies are consists of series of paddles types blades, pitched or flat, of appropriate shape. Here two consecutive blades move in opposite direction which creates laminar thinning of the material & facilitates uniform mix. Paddle type blades mounted on scrapping arms & welded to hollow shaft, have independent drive & has bottom support also. Paddles mounted on internal shaft creates relative movement of the material. Paddles mounted on internal shaft & hollow shaft rotates in anti-clockwise & clockwise direction respectively. The Shampoo Mixer is designed & fabricated to withstand perfect vacuum applied during the process for optimum mixing & to eliminate air entrapment as surfactant has tendency of forming suds. The vessel shall have a shell of suitable thickness with a hemispherical bottom and flanged top dish made out of S.S.304 plate. There is provision of bottom entry homogenizer in the same vessel which homogenizes all ingredients & hence there is no need to go for external inline homogenizer otherwise problem of aeration will increase process time. The vessel shall be suitable for 700mm vacuum and internal pressure of 3 kgs/CM2. There will be a suitable outlet provided for the product discharge.