| Material | Stainless Steel |

| Capacity | 5000 Kg/hr |

| Weight (kg) | 500-1500 Kilograms (kg) |

| Computerized | No |

| Automatic | Yes |

| Voltage | 440 Volt (v) |

| Dimension (L*W*H) | 92 X 88X 77 Millimeter (mm) |

| Color | Blue |

| FOB Port | Nhava Sheva |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 4 Per Month |

| Delivery Time | 4 Week |

| Packaging Details | Wooden Box. |

| Main Export Market(s) | Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America, North America, Australia |

| Main Domestic Market | All India |

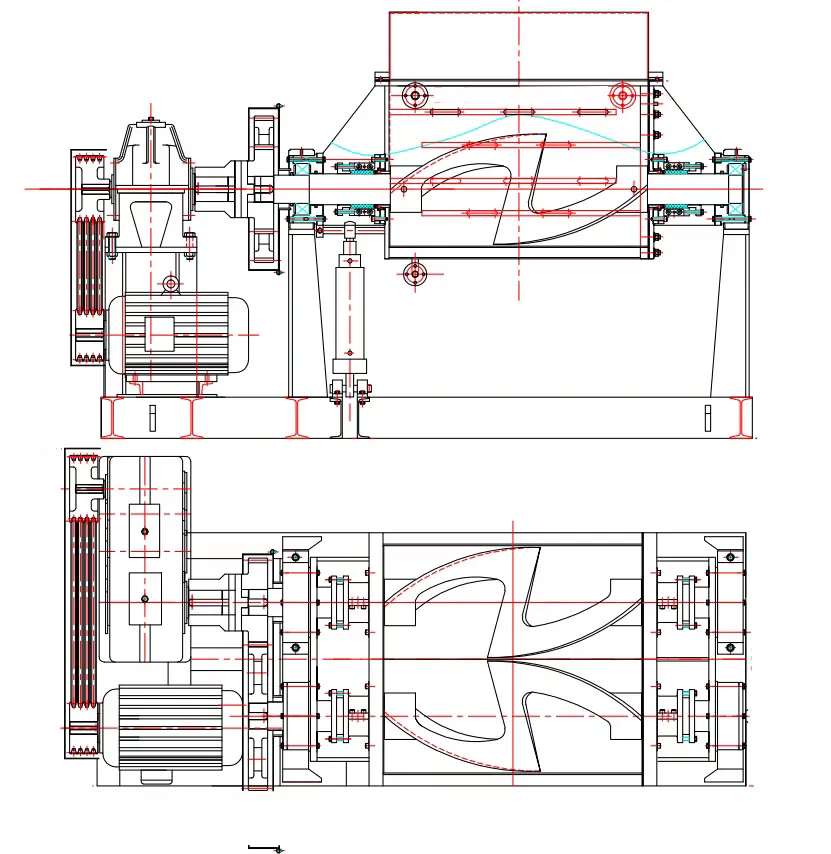

1. Uses: Sigma Mixer is widely applied to produce high-viscosity sealant, silicone rubber, neutral and acidic glass cement, chewing gum, bubble gum, paper pulp, and cellulose, and is also used in batteries, ink, pigments, dyes, pharmaceuticals, resins, plastics, rubber, cosmetics, and other industries.

Sigma Mixer is used to knead, mix, crush, disperse and re-polymerize high-viscosity paste or elastoplastic materials, which can not be processed by available powder mixers and liquid blenders. Sigma Mixer is the ideal equipment for all kinds of chemical products and has the merits of stirring evenly, kneading efficiently, and having no dead corners. The materials are scraped, stretched, folded, and squeezed among the blade, slot wall, and ridge-like protrusions. The materials cycle from one end of the impeller to the other. The two mixing paddles are tangent and spin at different speeds to complete the kneading process.

With an experience of over two decades in handling the various process applications in Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Bulk Drugs, API and Nutraceuticals. We offer well-engineered and optimum agitation solutions, mixing agitators, industrial agitators, chemical agitator, industrial agitator, chemical agitators, for all your Mixing Tasks.

Offering Sigma Mixer for Various Mixing Application like:

| Models | Working Capacity | Gross Capacity | Main Motor | Extruder Motor |

| SME – 50 | 50 Liters | 80 Liters | 7.5 H.P. | 1.5 H.P. |

| SME – 75 | 75 Liters | 110 Liters | 10 H.P. | 2 H.P. |

| SME – 100 | 100 Liters | 150 Liters | 15 H.P. | 2 H.P. |

| SME – 150 | 150 Liters | 200 Liters | 20 H.P. | 3 H.P. |

| SME – 200 | 200 Liters | 300 Liters | 25 H.P. | 3 H.P. |

| SME – 400 | 400 Liters | 550 Liters | 40 H.P. | 5 H.P. |

| SME – 500 | 500 Liters | 750 Liters | 50 H.P. | 5 H.P. |

| SME – 750 | 750 Liters | 1150 Liters | 60 H.P. | 5 H.P. |

| SME – 1000 | 1000 Liters | 1500 Liters | 70 H.P. | 7.5 H.P. |

| SME – 1500 | 1500 Liters | 2100 Liters | 80 H.P. | 7.5 H.P. |

| SME – 2000 | 2000 Liters | 2600 Liters | 90 H.P. | 10 H.P. |

| SME – 3000 | 3000 Liters | 3800 Liters | 120 H.P. | 10 H.P. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.