Mud agitators are highly efficient mud mixing units offered in a wide variety of custom sizes and configurations to accommodate virtually any mud tank. Both horizontal and vertical drive configurations are available for all sizes of mud agitators. The horizontal drive is designed for installations having limited space above the mud tank. The vertical drive agitator employs and all helical gearing system, the horizontal drive utilises a helical bevel system to drive the agitator shaft.

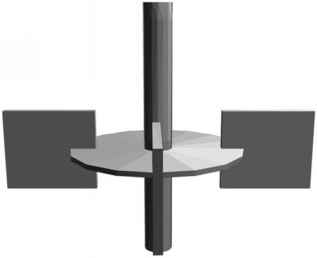

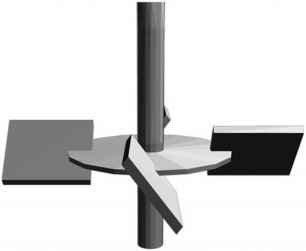

The agitator shaft can have one or two straight or canted mixing impellers.

Mud agitators stir a mud slurry to maintain suspension of solids. The agitator is mounted on top of the mud tank and has one or two impellers immersed in the mud slurry. The impeller shaft is directly coupled to an electric drive motor that is available in many different horsepower ratings from 3hp to 30hp.

Each agitator is designed for the specific application, taking into account parameters such as tank size, tank depth and mud characteristics. For vertical configurations the drive motor rotates the impeller shaft through an all helical gear drive. For horizontal designs the motor is connected through a combination of helical and bevel gears. Both designs permit mounting of one or two impellers having either straight or canted blades.

The impeller is secured to the shaft by a locking plate and prevented from rotating by a key inserted into the impeller shaft. ABFINDIA recommend that the impeller vertical location on the shaft is determined as a height from the tank bottom corresponding to the impeller diameter times 0.75. For example a 20" impeller should be mounted 15" above the bottom. ABFINDIA recommend straight impeller blades for tanks under 5' deep and canted impeller blades for deeper tanks. If dual impellers are to be used then the straight blades are mounted on the bottom and the canted blade impeller is mounted at a point approximately two thirds above the tank bottom.

The impeller is secured to the shaft by a locking plate and prevented from rotating by a key inserted into the impeller shaft. SCL recommend that the impeller vertical location on the shaft is determined as a height from the tank bottom corresponding to the impeller diameter times 0.75. For example a 20" impeller should be mounted 15" above the bottom. ABFINDIA recommend straight impeller blades for tanks under 5" deep and canted impeller blades for deeper tanks. If dual impellers are to be used then the straight blades are mounted on the bottom and the canted blade impeller is mounted at a point approximately two thirds above the tank bottom.

The keyed motor and driven impeller shafts are rigidly connected by a multi piece coupling, which uses taper lock bushings to secure the shafts together. Shaft lengths are customised to suit the customer requirements. For shafts longer than 8 Ft a stabiliser is mounted on the tank bottom to support the lower end of the shaft.

Rotation of the drive motor is transferred to the impeller shaft through a directly coupled gear drive. The drive is a reduction gearbox and is factory assembled to the drive motor. The drive is sized to apply the maximum torque required to produce the design impeller speed of 60 rpm.

Impellers are available in diameters ranging from 20" to 52" to meet the needs of the specific size of mud tanks. The impeller diameter is generally determined by the size of the tank. Larger or deeper tanks employ dual impeller units having a secondary impeller mounted closer to the mud surface. The impeller is mounted on the shaft using a taper lock bushing. A key is inserted in the impeller shaft and locks the impeller to the shaft to prevent rotation. The straight blade configuration disperses mud laterally while the canted impeller blade adds a vertical component to the mixing process. Canted impeller blades are recommended for near the bottom of tanks more than 5" deep, or where other forces of flow factor may be absent in the tank. Shafts and Impellers can be constructed from different materials including Stainless Steel and Hardox.